110.

2024

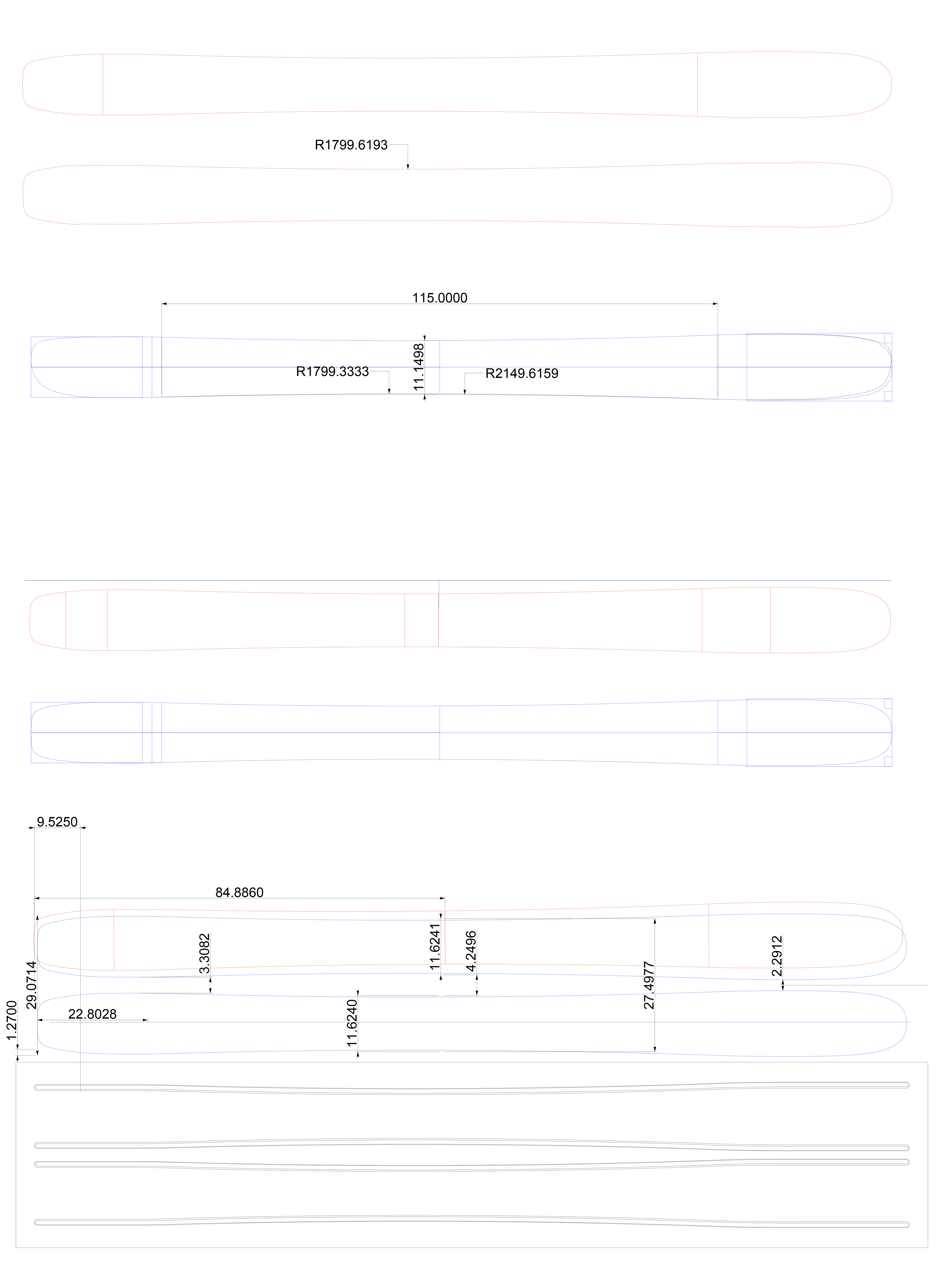

178cm

Material: Ash wood, steel, PTEX,

UHMW, carbon fiber, basalt, Innegra.

Processes: CAD,

CAM, Wood and plastic shaping, wet layup vacuum bagging.

The 110 ski started as a high school project, where I developed a ski design and manufacturing process through many iterations. After college, I was planning a ski trip and wanted a new generation of the ski, so I dug out the mold and jigs and started planning the design and reinforcement schedule. Having landed on a base and sidecut profile that was capable of charging through crud, making sweeping carves, and floating in powder, I knew that for the latest generation of the ski, I should focus on the flex and damping of the core. I landed on an ash wood core for its flexibility and density, which help the ski feel planted on the slope. I incorporated layers of carbon fiber, basalt, and Innegra, enhancing the ski’s flex pattern, torsional stiffness, and damping characteristics.